Drop Free Glass

Drop Free Glass (DFG) is advanced glass which can promptly and efficiently remove various contaminants such as rain water,

fog, frost and dust generated on the surface using a unique microfluidic technology.

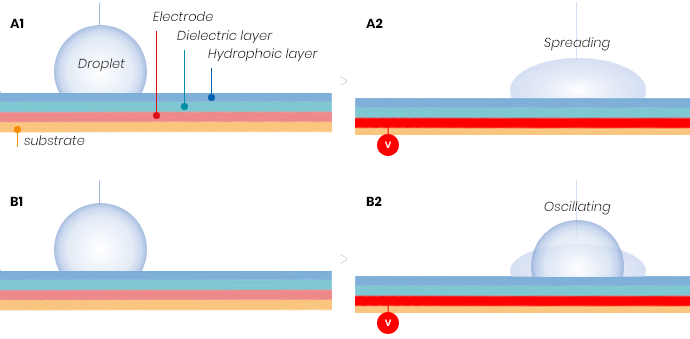

Drop Free Glass (DFG) is driven by a novel microfluidic technology. The DFG controls the surface tension of liquid droplets on the surface through the application of electric potentials.

MICROSYSTEMS has over 30 domestic and foreign source patents for the technology.

Drop Free Glass (DFG) removes droplets on the surface using a novel microfluidic technology. When liquid droplets are generated on the surfaces of cameras and sensors,

the DFG makes them oscillate and simultaneously repelled from the surfaces.

Drop Free Glass (DFG) can remove not only droplets such as rain and fog but also snow, oil, and dust. It can even remove a high viscous honey.

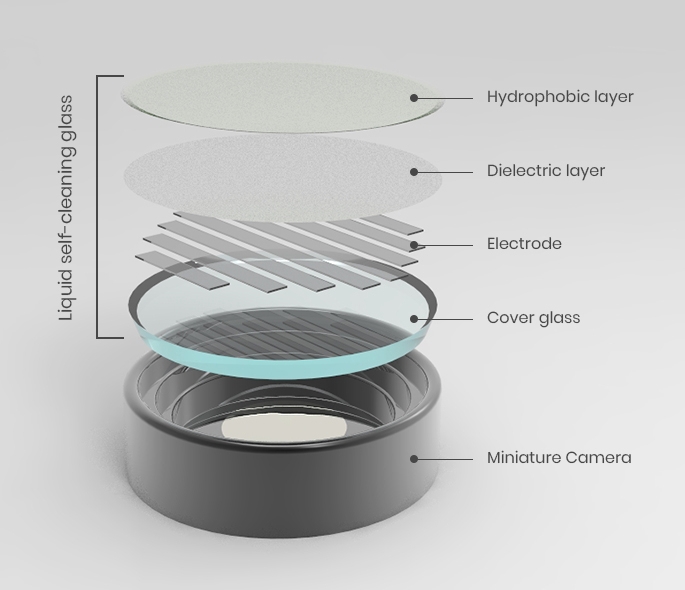

Drop Free Glass (DFG) has a simple structure consisting of electrode and dielectric layers. Hence, there is no need for complex mechanical driving devices,

resulting that the DFG is highly durable. In addition, It can be fabricated on any substrate such as glass and plastic.

-

Fast operation speed

Fast operation speedDrop Free Glass can promptly remove contaminants on the surface with fast operation speed (< 1 sec.) through novel microfluidic technologies.

-

No mechanical components

No mechanical componentsDrop Free Glass uses electric fields unlike the existing mechanical technologies; hence, there is no need for mechanical components, and consequently, the durability is excellent.

-

Low power consumption

Low power consumptionDrop Free Glass has a low power consumption (< 1 mW) as the flow of current is limited by a dieclectic layer.

-

Surprisingly small

Surprisingly smallDrop Free Glass consists of only electrode and dielectric layers of sub-micrometer thicknesses making the DFG miniaturization possible.

-

Easy to mass production

Easy to mass productionSince Drop Free Glass is manufactured by using semiconductor processes that have already been commercialized, it is easy to achieve mass production.

With the above advantages, Drop Free Glass (DFG) is expected to be applied not only to automotive cameras, but also windshield and side view mirrors in an automotive industry, and it is also expected to be applicable to various other industries such as drones and the Internet of Things.

-

Drone camera

-

Automotive window

-

Mirror

-

Glasses